DEPARTMENT LABORATORIES

OBJECTIVES:

- To be able to understand and handle design problems in a systematic manner.

- To gain practical experience in handling 2D drafting and 3D modeling software systems.

- To be able to apply CAD in real life applications.

- To understand the concepts G and M codes and manual part programming.

- To expose students to modern control systems (Fanuc, Siemens etc)

- To know the application of various CNC machines

- To expose students to modern CNC application machines EDM, EDM wire cut and Rapid Prototyping

The Lab has 60 Nos. of high end desktops connected in LAN, Switch based network for speedy internet access, High end software like CATIA V5R9, Pro-E, IDEAS 9.0, ANSYS 5.7.1, ARENA 10.0, SOLID WORKS 2006, UNIGRAPHICS NX4 (CAD), AND AUTODESK INVENTOR SERIES 5.3.

OBJECTIVES:

- To understand the basic concepts of computer numerical control (CNC) machine tool and CNC programming.

The Lab has Production model CNC lathe and CNC milling machines with CAM simulation softwares like CMAS, Edge CAM 10.75, Unigraphics NX4 (CAM), and Falcon make ROBOT RCS 6.

OBJECTIVES:

- To supplement the principles learnt in kinematics and Dynamics of Machinery.

- To understand how certain measuring devices are used for dynamic testing.

Dynamics and vibrations laboratory equipped with universal governor, whirling of shaft, gyroscopic couple and other various mechanisms.

OBJECTIVE:

- To understand the interdisciplinary applications of Electronics, Electrical, mechanicaland Computer Systems for the Control of Mechanical and Electronic Systems.

LIST OF MAJOR EQUIPMENTS

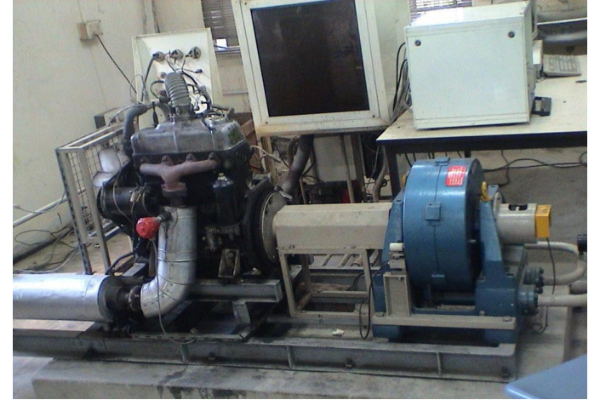

Internal Combustion Engines Lab.

IC engines laboratory with a fleet of two stroke and four stroke, diesel and petrol engines, single stage and multi stage compressors, constant and variable speed blowers.

OBJECTIVE:

To gain hands on experience on working of general purpose machine tools and on various manufacturing processes.

This lab consists of two sections,

1. General purpose machine tools:

Machine shop with conventional lathes, auto, capstan & turret lathes & spl. machines such as Universal milling machine, shapers, planners, grinders with special purpose tools section.

2. Special Purpose machine tools:

This section consists of planning machines, slotting machine, radial drilling machine, Automatic Lathe, Turret and capstan lathe, cylindrical surface grinders, Milling machine and cutter grinder, etc.

This lab is equipped with different shops.

Fitting and Carpentry shop is equipped with various fitting and carpentry devices and tools.

Smithy Shop is equipped with charcoal fired furnaces, power hammers, anvils, different types of sledge hammers, swage blocks, tongs, etc.

Foundry shop has moulding and casting tools and accessories like green sand, mould board, different types of hammers, trowels, types of patterns, etc.

Welding shop has arc welding and gas welding equipments with fitting and bench grinding machines, etc.

I.C Engine 2 stroke and 4 stroke model, 4-stroke Diesel Engine with mechanical & hydraulic loading. Single and Multi-cylinder Petrol Engine, Data Acquisition system.

Slip Gauge Set, Sine Bar, Sine Center, Profile Projector / Tool Makers Microscope, Mechanical / Electrical / Pneumatic Comparator, Temperature, displacement, force, torque and vibration Measuring Setup

For Online Grievance : onlinegrievance@jec.ac.in